Thanks to its ability to analyze large amounts of data in real time and make informed decisions, Artificial intelligence (AI) is ushering in a new era of innovation and efficiency in industrial operations.

As technology advances, the integration of AI into industrial processes promises to offer even greater benefits, driving significant changes and setting new standards for the industry’s future.

What is artificial intelligence and how does it intervene in manufacturing?

Essentially, AI encompasses a set of sophisticated technologies that enable systems to perceive their environment through data, relate to what they perceive, solve problems, and act toward a specific goal based on predefined algorithms.

Artificial intelligence‘s importance is increasing both in everyday use and industrial processes due to its significant advantages in efficiency, personalization, and informed decision-making. With technological growth, AI’s usage in industries is expected to become more widespread in the future.

In the industrial sector, AI can transform machines, robots, or software into “intelligent” entities using learning algorithms or machine learning. The latter refers to mechanisms that allow an intelligent machine to improve its capabilities and performance over time through self-learning processes. A process that relies on data detection and analysis, combined with mathematical and statistical models.

In addition to machine learning, there are deep learning models where learning is inspired by and emulates the functioning of the human brain. This involves the use of artificial neural networks designed with substantial computational capacity.

Industry 4.0 is one of the fields where machine learning processes play a crucial role in enhancing productivity, efficiency, and optimization levels.

AI Applications in Industry

Artificial intelligence is revolutionizing the industrial sector through several high-impact applications.

One of the most important uses of AI in industry is process automation: companies are increasingly leveraging artificial intelligence to automate a wide range of tasks, including manufacturing, logistics, and maintenance. Indeed, AI systems can manage product quality control in real time, reducing human error and improving efficiency. At the same time, artificial intelligence can optimize manufacturing operations by dynamically adjusting processes based on external conditions, thereby reducing operating costs and improving resource utilization.

Predictive maintenance is another critical application of AI in industrial operations. By integrating AI with the Internet of Things (IoT), companies can analyze the condition of machinery and equipment using precise mathematical models. This analysis helps predict and prevent potential failures, thereby increasing the reliability and lifespan of industrial equipment.

Moreover, artificial intelligence can play a significant role in both product customization and production planning. Its ability to analyze customer preferences and tailor products to meet specific needs helps companies understand different customer segments and design products that cater to their unique preferences, thereby enhancing customer satisfaction and loyalty. Simultaneously, AI proves invaluable in production planning by creating demand forecasting models that identify purchasing patterns and market trends. These models enable companies to plan production more effectively and avoid waste. Additionally, it enhances decision-making processes by analyzing vast amounts of data, ensuring more informed and strategic business decisions.

So, what are the practical benefits of AI for businesses and industries?

- Greater Efficiency: reduced process times, minimized human errors, and optimized revenues.

- Business Continuity: predictive logic in maintenance and production to reduce costs, prevent failures, and improve productivity.

- Control: remotely monitoring the entire production cycle in real-time, reducing human error and improving quality. Predictive control is also possible, forecasting problems or failures.

- Safety: reduced risks for workers through automation and predictive maintenance.

System Electronics’ new AI solution: ASTRIAL

As we have seen, artificial intelligence will become a key asset, and its integration will become increasingly necessary for companies aiming to remain competitive.

To fully leverage the potential of AI, it is crucial to have a reliable and experienced partner, and System Electronics, a brand of Coesia, offers the expertise and innovative solutions needed to integrate artificial intelligence into your industrial processes seamlessly.

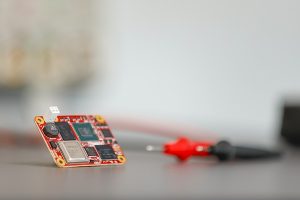

System Electronics has entered the AI world with ASTRIAL, a technology platform inspired by the community of innovators for the industrial grade. It’s a system-on-module created for highly demanding projects in terms of computational capacity and power density that stands out due to its unique combination of CM4 format, Hailo8 accelerator, and imx8plus microcontroller integrated into a highly compact device. This combination offers high computing power compatible with a wide range of development systems already available in the market.

ASTRIAL’s added value lies in its use of industrial-grade components designed to withstand production environment stress, along with long-term support guaranteed to customers.

By partnering with System Electronics, you can ensure that your company is at the forefront of technological advancement, driving efficiency, productivity, and customization.

For more information and to discuss how System Electronics can help your business harness the power of AI, contact us today and visit systemelectronics.ai.